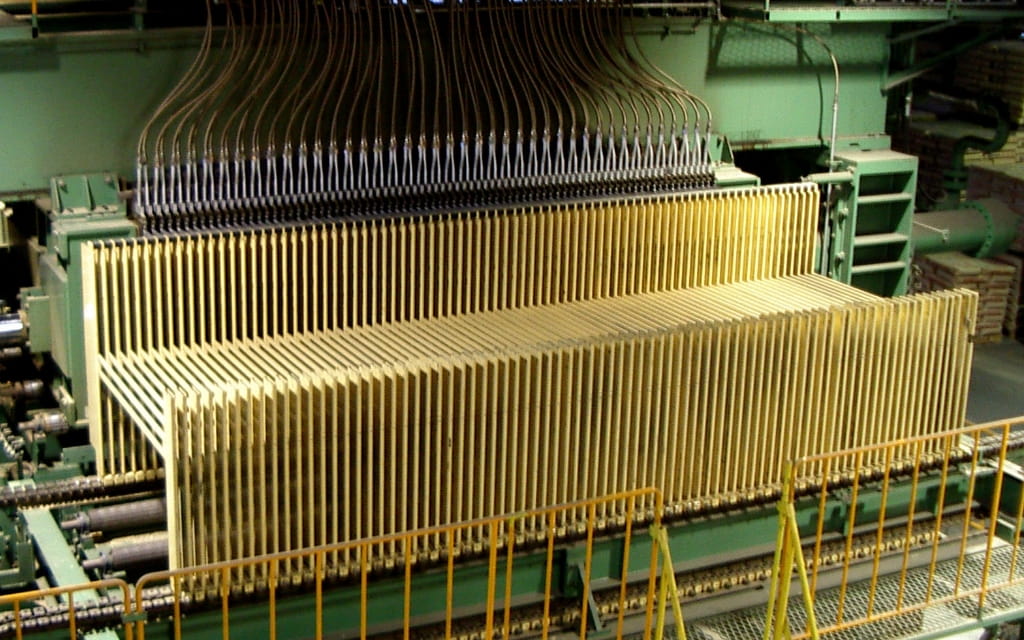

Taihei’s Horizontal Hot Press performs the critical heat and pressure bonding process that transforms layered veneer into durable plywood. Unlike traditional vertical presses, Taihei’s design places hot platens vertically and applies compression force horizontally. This innovative configuration ensures more uniform pressure, enhanced product quality, and greater operational efficiency.

Traditional vertical presses place uneven pressure across layers due to the weight load of the stacked platens, often resulting in variation and excessive material sanding. Taihei’s horizontal configuration ensures consistent compression at all levels, minimizing thickness differences and preserving more of the original plywood. That means higher yields and less waste.

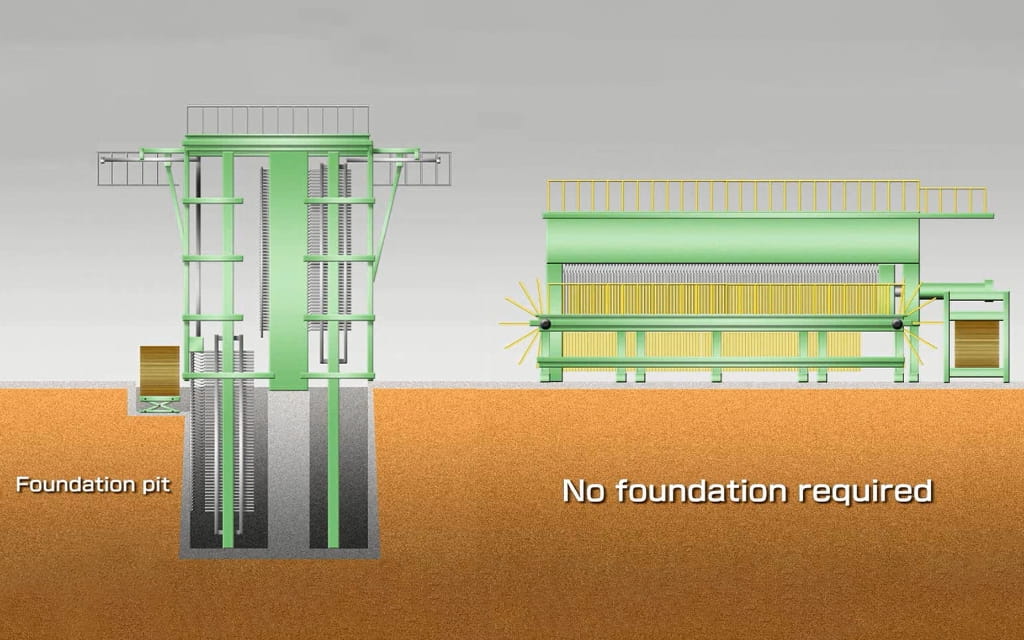

The horizontal press can be installed directly on the factory floor with no need for deep foundation pits or accumulator tanks. Taihei’s horizontal configuration. Its reduced height enables installation in low-ceiling spaces, making it ideal for upgrades or replacements. With less construction time and lower overhead costs, it’s a smart investment for both new facilities and retrofit operations.

Thanks to its scalable design—supporting up to 140 slots—the Taihei Horizontal Hot Press can process larger plywood volumes than traditional presses. One horizontal unit can replace multiple vertical units, reducing the number of required operators. Taihei’s horizontal configuration. Under automated mode, just one operator can manage the entire press, streamlining labor and improving efficiency.

With its reduced height and shallow or no foundation pit, the Taihei Horizontal Hot Press offers improved accessibility and safety. Maintenance is safer and simpler, and the risk of accidents due to fall or confined spaces is reduced—creating a safer work environment overall.

The IRETARO auto-feed system detects double-panel stacking and feeds up to 100 thin panels quickly and reliably—preventing misfeeds and panel damage. Compatible with both horizontal and vertical presses, it handles a broad range of panel thicknesses and includes an optional pallet auto-return system for even greater efficiency.

Every Taihei machine is precision-engineered to deliver lasting performance—crafted in-house using proven technology and the latest innovations to meet your toughest production demands.

Years of Innovation

Japan & U.S. Locations

Employees

Insights from the CEO

“Our most enduring asset is simple: trusted relationships with our customers, partners, and employees.”

“We’re are advancing wood technology to help build a truly sustainable world.”

“We’re committed to keeping pace with new technologies and practices while honoring the principles that got us here.”