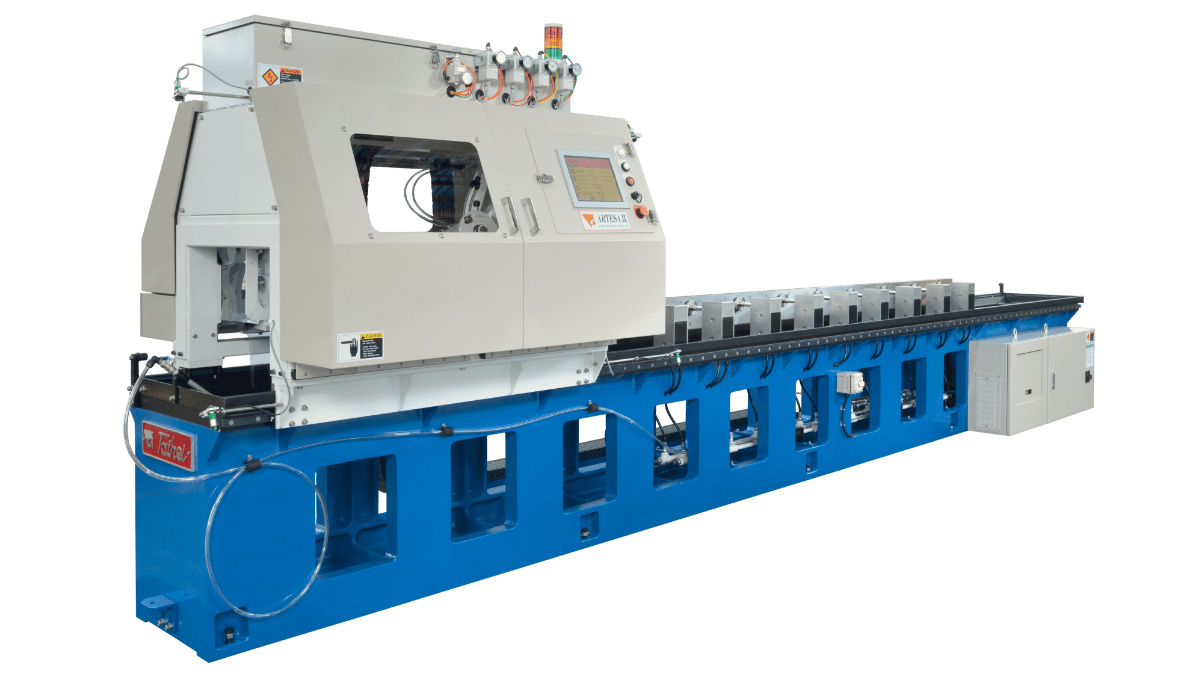

The Knife Grinder ARTESA I performs rough knife sharpening and is mainly used for base grinding on veneer knives. The Knife Honer ARTESA II performs precision honing of small knife angles along knife edges that have been ground by the Knife Grinder ARTESA I.

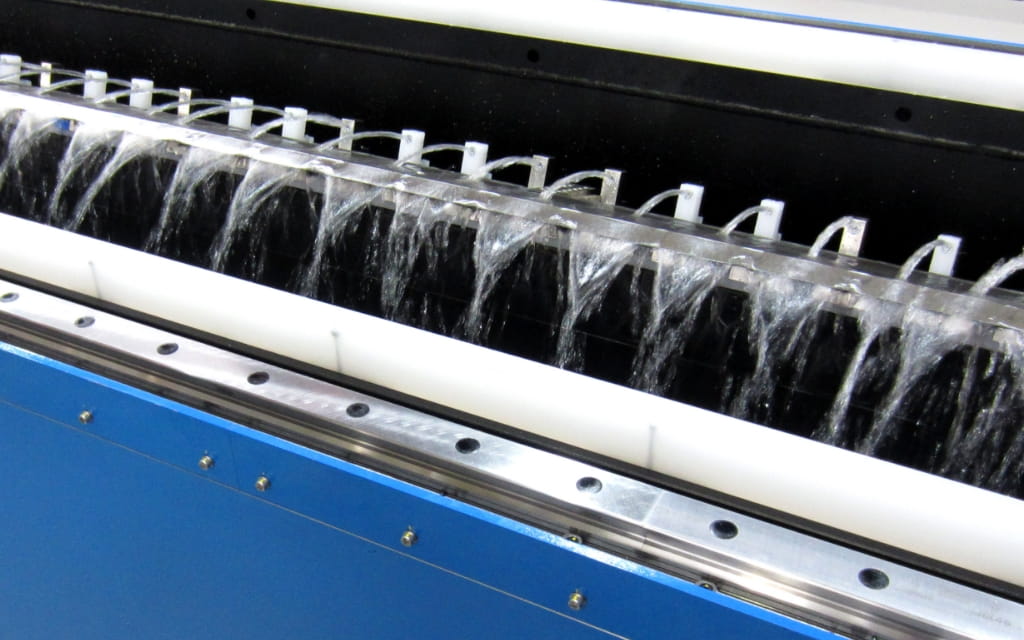

A large-volume cooling system stops thermal distortion during grinding. This makes it easier to grind knives with excellent straightness, which can be expected to improve and stabilize veneer quality. Three types of grindstones (rough, finishing, and back grinding) and automatic adjustment of grinding direction (up or down cutting) provide faster honing and improved precision.

Input a grinding pattern to fully automate the entire grinding process for efficiency and accuracy.

Using three kinds of grindstones (blade face: 46#, 150#; blade back: 150#) the Artesa I automatically switches between up cuts and down cuts, for more efficient grinding compared to conventional machines. Down cut finishing produces blades with no chips and high straightness.

The Artesa I can be easily adapted to grind many kinds of knives, not just veneer knives, including chipper knives, clipper knives, composer knives, flaker knives, and so on.

The large-volume coolant system mitigates grinding friction heat and suppresses thermal distortion of the blade during griding. The result is a high straightness precision of less than 0.05 mm (0.002 inch) variance over 2,750 mm (9 feet). This produces high-quality veneer with smooth surfaces and more consistent thickness.

The Artesa II uses precise air control and enables ultra-high accuracy edge cutting with 20-micron land width.

Honing patterns are automatically stored, making it easy to reproduce blade shapes corresponding to the raw timber, which in turn improves and stabilizes veneer quality.

Proprietary air balancing mechanism stabilizes grinding pressures, thus enabling smooth copy honing to form land widths of 0.02 mm (0.00008 in). Sharpening takes into account the balance of forces applied to the cutting edge to produce knives with excellent sharpness and edge retention (durability). Grindstones: #1000 and #8000 (front and rear)

Multiple knife angles can be added along the knife edge to customize the knife for different types of logs. This enables even more consistent and high-quality veneer peeling. In addition, forming an oval shape with numerous small knife angles on the knife's cutting edge improves durability compared to normal honing processes.

The hardness of raw timber differs depending on the type of tree, and each type requires a certain blade shape. The Knife Honer ARTESA II can create precise stepped angles on the face and reverse of the blade, and save up to 39 sets of design data for these patterns. Cameras can be used after honing to verify and manage the cutting edge.

As with the Knife Grinder ARTESA I, grinding patterns can be input to fully automate the entire grinding process, further enhancing your operations and overall efficiency.

Every Taihei machine is precision-engineered to deliver lasting performance—crafted in-house using proven technology and the latest innovations to meet your toughest production demands.

Years of Innovation

Japan & U.S. Locations

Employees

Insights from the CEO

“Our most enduring asset is simple: trusted relationships with our customers, partners, and employees.”

“We’re are advancing wood technology to help build a truly sustainable world.”

“We’re committed to keeping pace with new technologies and practices while honoring the principles that got us here.”